Process

Maple

Cherry

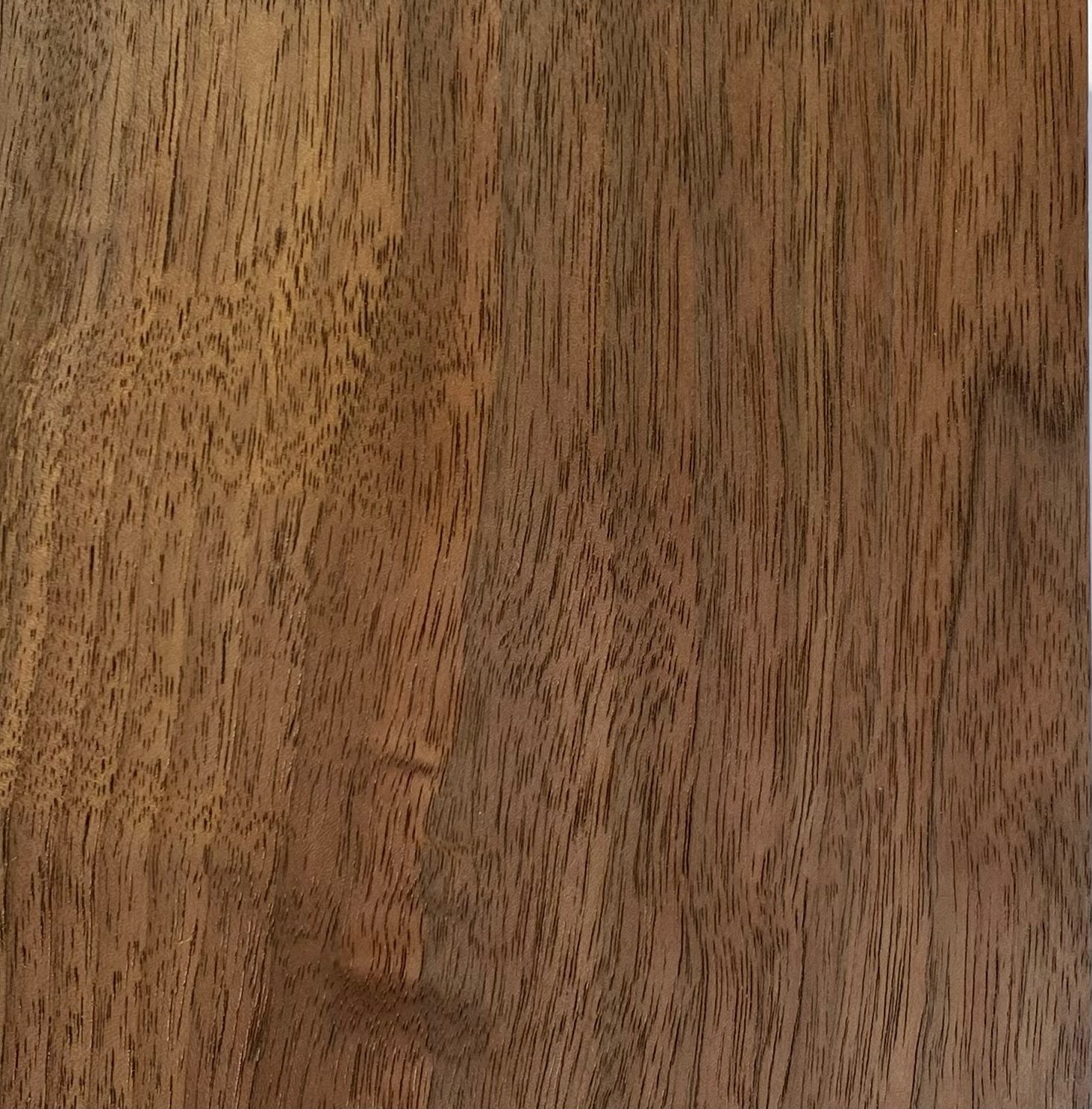

Walnut

Ash

About Me

My name is Christopher Keen and I reside in Franklinville, New Jersey. I design and build custom hardwood furniture.

I have always been one to work with my hands and fell in love with woodworking a few years ago. As is common with most woodworkers, I began building some pieces of DIY furniture for my home and became hooked. The creativity, problem solving, and making something useful (but also appealing to the eyes), are some of the things that drew me into this field. My first projects would not have gotten a passing grade from any shop teacher, but I have come a long way since then and still continue to learn and perfect this craft.

About My Work

Design

The inspiration for the work and designs I do come mainly from Shaker origin, which emphasizes craftsmanship, simplicity, and usefulness.

I am a one man shop and build one piece at a time, using sustainably harvested hardwoods from local lumber yards within a couple hours of my shop. These hardwoods are walnut, maple, cherry, ash, and some others. Each species varies in color, grain, and character, but whatever one you choose, it will be carefully selected from the lumberyard by me, to build you a beautiful piece with matching grain and color.

I use power tools and hand tools in my building process. Efficiency and speed come with power tools, detail and craftsmanship come with hand tools. I employ furniture making techniques that have been used for centuries. Mortise and tenon joints, for joining aprons to table legs. Dovetails for joining edges on a case, or a drawer. Dadoes and rabbets for joining a shelf to the side of a bookcase. All of these examples are ways woodworkers of old built furniture that lasted for lifetimes, which is also my goal.

Another important factor in making lasting furniture is taking wood movement into account. Even though it’s not a tree anymore, wood is still alive, moving and expanding with the changing humidity of the seasons. In the spring and summer, moisture will get into the cells of the wood, causing it to expand. In the winter when the humidity drops, the wood will shrink. This has to be considered and applied when building a piece. If it’s a table your getting, the table top will be fastened to the base in such a way that will allow it to expand and shrink.

I do not use wood stains in my work. Stains are mainly used in mass produced furniture to make cheap wood look more expensive. Then they are sprayed with a plastic film finish which when scratched or damaged, is basically non-repairable cause the whole piece has to be stripped and refinished.

I use a hand rubbed oil finish on my furniture. Oil finishes soak into the wood, and are very sufficient in protecting your piece. They reveal and highlight the natural beauty of wood and don’t sit on top like film finishes do such as polyurethane. Oil finishes are also very easily repaired.